Designed to protect and care for every embryo

The BT37 MarkII combines providing a consistent and optimal environment for embryo development with improved functionality and ease of use ensuring that it helps protect and care for your embryo’s and gametes throughout their culture.

The BT37 MarkII provides precision control of all the parameters required to ensure optimal homeostatic conditions are maintained throughout the whole chamber.

The BT37 MarkII is packed with new and improved features to ensure the incubator is easy and intuitive to use.

Optimum Environment Conditions

The specially designed chamber base ensures heat transfers directly to the culture dish ensuring embryos are keep at optimal temperature not just the chamber base. The heated chamber base and lid ensures that temperature consistent throughout the chamber, with variation across the chamber no greater that 0.2°C or across a single dish of 0.1°C. The BT37 MarkII uses premixed bottled gas or supply via an external gas mixer e.g. Okolabs TriGas to provide the optimum pH environment for your embryos or gametes.

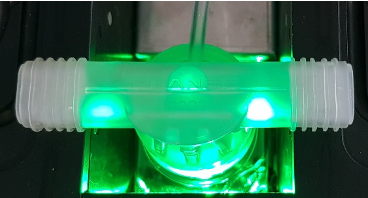

New Generation Humidification system

The BT37 MarkII can be operated using either the original BT37 three tube bottle design or the new improved BT37 MarkII bottle design. The new BT37 MarkII improved humidification bottle makes changing the bottle quick and easy as well as reducing the risk of gas flow failure from pinched or kinked tubes. The BT37 MarkII can be run as a non humidified environment by not filling the bottle with water (humidification bottle must still be fitted).

Easy and Intuitive to Use

The touchscreen display provides clear information regarding the chamber conditions, user alert and alarm messages and the system setup menus* at a glance ensuring the incubator is simple and intuitive to use direct from the on screen menus and messages.

*System operation is fully password protected

Comprehensive Protection for Embryos

Embryos inside the BT37MkII are protected by a comprehensive range of alarms and reminders. In additional to the individual chamber alarm indicators the main touchscreen clearly display alerts and alarm messages to allow quick identification and rectification of any potential situations or errors before damage is done to the embryo’s inside. The BT37 MarkII has extensive access for independent monitor of various critical parameters including temperature, CO2 and pH as well as connections for external monitoring systems to provide alerts even when the facility is unmanned.

Embryos inside the BT37MkII are protected by a comprehensive range of alarms and reminders. In additional to the individual chamber alarm indicators the main touchscreen clearly display alerts and alarm messages to allow quick identification and rectification of any potential situations or errors before damage is done to the embryo’s inside. The BT37 MarkII has extensive access for independent monitor of various critical parameters including temperature, CO2 and pH as well as connections for external monitoring systems to provide alerts even when the facility is unmanned.

Improved Chamber Access

The ergonomic and non-intrusive twist lock lid catches have been designed to ensure not only that a good seal is maintained enabling the optimum environment is reinstated quickly post lid open, but also that single handed access to the chambers is simpler and easier. Simply twist and lift the lid using the catch.

The ergonomic and non-intrusive twist lock lid catches have been designed to ensure not only that a good seal is maintained enabling the optimum environment is reinstated quickly post lid open, but also that single handed access to the chambers is simpler and easier. Simply twist and lift the lid using the catch.

In Built Convenience

The soft close lids system fitted to the BT37 MarkII prevents accidental lids closing whilst accessing the embryo’s within the chamber. Lids slamming closed accidentally potentially disrupts the culture dishes and embryo’s inside.

The soft close lids system fitted to the BT37 MarkII prevents accidental lids closing whilst accessing the embryo’s within the chamber. Lids slamming closed accidentally potentially disrupts the culture dishes and embryo’s inside.

Minimal Down time

We know that it is important to our customers that down time when equipment is not available for use is kept to a minimum therefore the BT37 MarkII incorporates numerous hidden changes all designed to reduce the time the incubator is out of service for maintenance.

We know that it is important to our customers that down time when equipment is not available for use is kept to a minimum therefore the BT37 MarkII incorporates numerous hidden changes all designed to reduce the time the incubator is out of service for maintenance.

Specifications

| System | |

| Dimensions | 435 mm wide x 330 mm deep x 185 mm high |

| Weight | 17 kg |

| Storage temperature | -10 °C to +50 °C |

| Storage humidity | 5% to 95% relative humidity non-condensing |

| Weight: incubation chamber | 17 kg |

| Storage special instructions | Recharge every 4 months by connecting to the mains power supply for 24 hours. |

| Operating environment | For indoor use only |

| Operating temperature | +5 °C to +40 °C for safe operation |

| Operating humidity | 20 % to 80 % relative humidity non-condensing decreasing linearly to 50 % relative humidity at 40 °C. |

| Altitude | up to 2000 m |

| Pollution degree | Pollution degree 2 (BS EN61010-1) |

| Control | |

| Temperature control range | (ambient + 5 °C) to (ambient + 20 °C) 40 °C max. |

| Temperature measurement accuracy | ± 0.2 °C |

| Temperature control accuracy | ± 0.1 °C measured after any transient effects due to set-point changes have subsided. |

| Flow control range | 0 ml/minute to 900 mL/minute Normalised to 0 C , 50% RH and 1 bar. |

| Flow accuracy | The greater of ± 10% or ± 3 ml/minute |

| Flow control accuracy | The greater of ± 5% or ± 2 ml/minute measured after any transient effects due to set-point changes have subsided. |

| Accuracies apply at the calibration points. The system is factory calibrated for an operating temperature of 37°C, nominal bleed flow of 30 mL/min and a purge at 360mL/min. | |

| Capacity | |

| Dishes per chamber | 4 x NUNC 4 well dishes, 4 x NUNC 60 mm Petri dishes 10 x NUNC 30 mm Petri dishes 4 x MINITUB 5 well dishes 4 x FALCON 60 mm Petri dishes |

| Power |

|

| Power requirements | 100 - 240 V~ 50/60Hz 2A |

| Internal battery backup | Gelled sealed lead acid battery 12V x 12 A.h |

| Gas supply |

|

| Gas supply | Premixed gas. Typically 6% CO2, 5% O2, 89% N2 |

| Supply pressure | 1.5 ± 0.15 bar |

| Connectors | SWAGELOK 1/4" tube fitting |

| Humidifier Bottle and Filter Kits - The humidifier water bottle and filter must be replaced every 28 days (4 weeks) |

|

| Order Code | Description |

| AY102295 | BT37 MarkI three tube humidifier bottle & filter kit (pack of six) |

| AY200246 | BT37 MarkII single tube humidifier bottle and filter kit (pack of six) |