Over the last year or so there have been reports in the press on problems with samples stored in liquid nitrogen. Cryo storage is such a reliable method that it is often taken for granted - equipment is generally very robust and supply of liquid nitrogen, LN2, is typically very reliable. Patients as well as new entrants to the field are often surprised to learn that both the freezing of a sample, and its long-term storage, can be more complicated than they seem.

Over the last year or so there have been reports in the press on problems with samples stored in liquid nitrogen. Cryo storage is such a reliable method that it is often taken for granted - equipment is generally very robust and supply of liquid nitrogen, LN2, is typically very reliable. Patients as well as new entrants to the field are often surprised to learn that both the freezing of a sample, and its long-term storage, can be more complicated than they seem.

Many people, even those working in ART laboratories, remain unaware that specimens in cryogenic storage will suffer damage due to ice recrystallization when their temperature rises above -132°C (the ice transition point of water). And, the smaller the specimen the greater risk it is at, because its low thermal mass will allow its temperature to rise more quickly, and hence follow more closely, the rising external temperature, that of the storage environment. So the risk of ice recrystallization damage increases when comparing cryotubes to straws to vitrified embryo carrier devices.

Quality and Risk Management in the IVF Laboratory In a definitive textbook on the subject on quality and risk management in the IVF lab, Drs Sharon and David Mortimer (pictured here) provide extensive background on the whole topic including explaining general principles applicable to managing risk in an Assisted Reproduction lab’s cryobank.

In a definitive textbook on the subject on quality and risk management in the IVF lab, Drs Sharon and David Mortimer (pictured here) provide extensive background on the whole topic including explaining general principles applicable to managing risk in an Assisted Reproduction lab’s cryobank.

In Chapter 8 “Managing Risk” there is a section on “Monitoring storage cryotanks” where they recount a personal experience of dealing with a degrading dewar and, based on that experience, provide a series of recommendations for routine good practice. And as an extension to the book, Dr David Mortimer has provided the following practical advice.

When using liquid storage in small cryotanks (e.g. up to 50 litres):

- Top up the tanks regularly at quite strict weekly intervals – but before doing so measure and record in a logbook the level to which the LN2 has fallen. Performing weekly re-fillings, rather than more frequent top-ups, is not unreasonable when a typical tank (e.g. Taylor Wharton HC35) has a static working time of more than 11 weeks. Then use these measurements to create a control chart – a Shewhart chart - so that not only can unusually low levels be readily identified, but degrading performance of the tank will be seen as a series of decreasing levels of remaining LN2 prior to top-up.

- In addition, tanks should be monitored for temperature and LN2 level with sensors connected to an automatic dial-out alarm system. Since the temperature of LN2 will always be -196°C the temperature sensor should be placed somewhere just below the typical level to which the LN2 will have fallen after a week of normal operational use and set to alarm at, say, -160°C. The LN2 level sensor should be located a short distance above where the uppermost specimen is held in storage.

When using liquid storage in large cryotanks of say 150 litres and more:

- These tanks must be connected to a large LN2 supply so they can operate on auto-fill.

Note: Ideally the cryotank controller should be “smart” and able to communicate with external monitoring software to allow logging of the amount of LN2 used; these data can then be used to generate an alarm should usage increase beyond a certain limit. An example of this would be the MVE TEC 3000 controller from Chart Industries combined with Planer’s DATAssure software. - Temperature and LN2 level sensors should be installed using the same principles as with small tanks and connected to an automatic dial-out system.

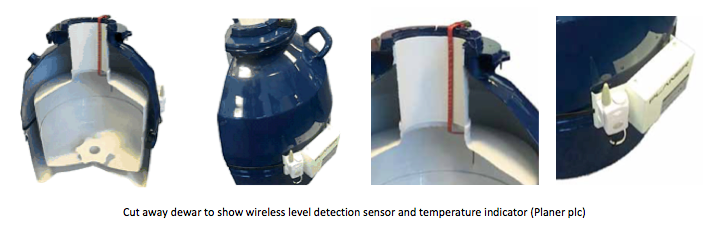

When using vapour storage in smaller dewars manual monitoring of the LN2 level is impractical, and a combination of LN2 level and temperature sensors should be used:

Locate the temperature sensor a good distance above the uppermost specimen in storage and have it alarm when the measured temperature falls below -140°C (which is considered to be the limit for safe vapour storage).

- Locate the LN2 level sensor at the manufacturer’s recommended minimum LN2 level for safe operation of the cryotank.

- When using vapour storage in large dewars the same principles for positioning the temperature and LN2 level sensors as in small dewars apply. However, because these tanks operate on auto-fill their regular consumption of LN2 should be monitored as described for large liquid storage dewars.

At Planer we are keen to promote safe cryo storage. As well as controlled rate freezers we sell vessels, alarm systems, monitoring systems and cryo transport loggers through our distributors available all over the world.

For further information

For Planer Monitoring: https://planer.com/products/alarms-a-monitoring/datassure-laboratory-wireless-alarm-monitoring-system.html

For ‘Quality and Risk Management in the IVF Laboratory’: http://www.cambridge.org/